BSZ1

- 5% Impact Modified PA6

- Available in Natural, Black, or Custom Color Options

- Product Benefits: Low-Temperature Impact Resistance, High Toughness, Surface Modification

- Certificate: RoHS, REACH

- Scroll down to download PDF version

5% Low-Temperature Impact Resistant Nylon 6

Product Overview

5% Low-Temperature Impact Resistant Nylon 6 (5% Impact Modified PA6) is a high-toughness material categorized as impact resistant plastics, designed for low-temperature applications. This nylon material, enhanced with an advanced impact modifier, offers excellent toughness and addresses the brittleness that often occurs in plastics under cold conditions. It also features superior surface reinforcement, minimizing fiber floatation and improving surface smoothness during injection molding, which significantly enhances the aesthetic appeal of finished products.

The PA6 5% Impact Resistant material uses specially formulated impact modifiers to further boost its impact strength, crack resistance, and dimensional stability. It is suitable for use in automotive components, outdoor equipment parts, stroller accessories, and household items that require basic elasticity and strength. Its low moisture absorption ensures stable performance in humid environments, making it a versatile choice for a variety of impact resistant plastics applications.

Technical Specifications

-

Material: Nylon 6 (PA6/ Polyamide 6/ Nylon 6)

-

Impact Modifier Content: 5% Acid Modified Elastomer

-

Tensile Strength: 50 MPa

-

Elongation at Break: >100%

-

Notched Impact Strength (23°C): 20 kJ/m²

-

Specific Gravity/Density: 1.12 g/cm³

-

Melting Point: 230°C

-

Colors: Natural, Black, or Custom Colors

Application Scenarios

5% Low-Temperature Impact Resistant Nylon 6 is widely used in the automotive industry, electronics, home appliances, and furniture:

-

Stroller Accessories: Components like safety buckles and auxiliary wheels, offering excellent impact resistance.

-

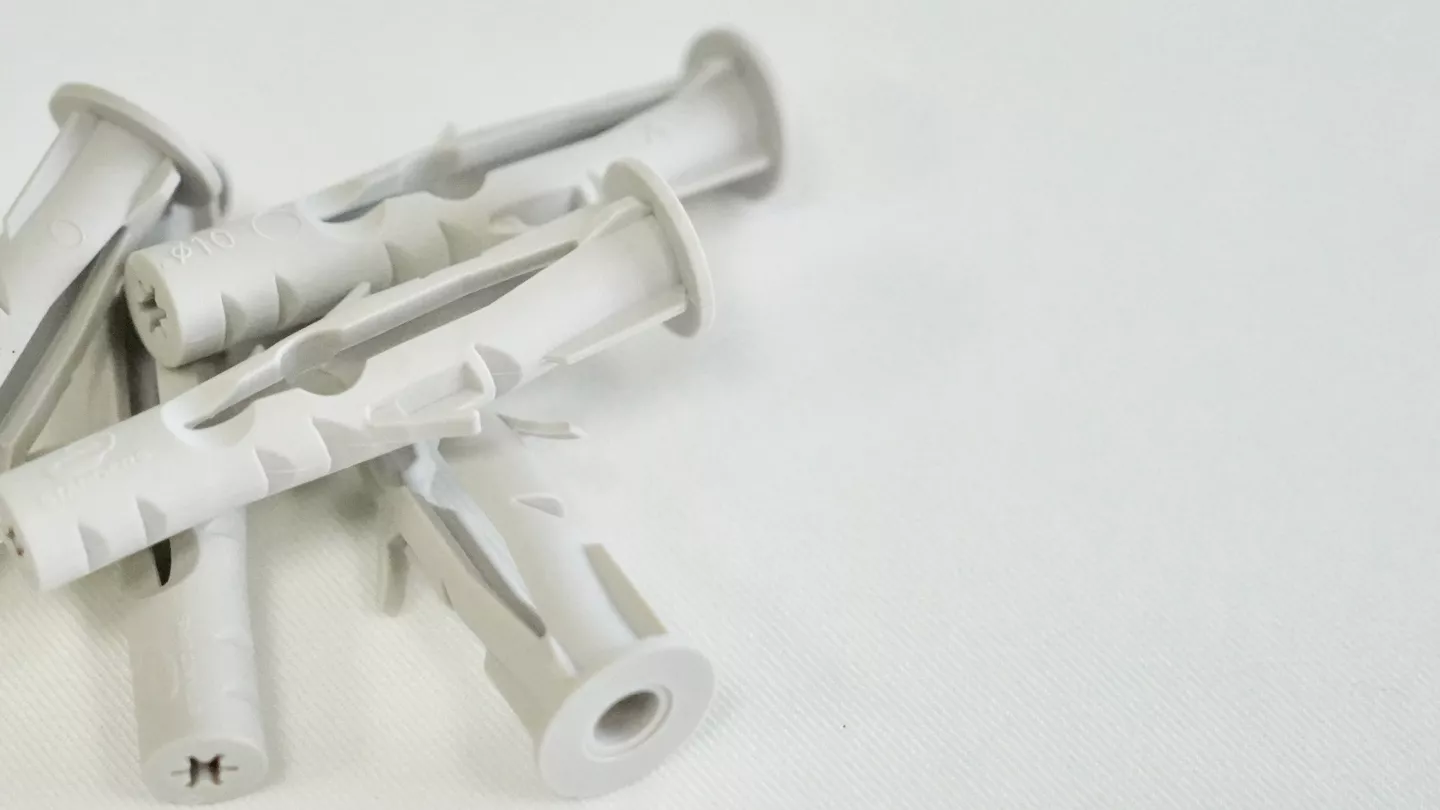

Household Items: Ideal for items like drainage channels and wall anchors, owing to its superior elasticity and rigidity.

Comparison with Other Impact-Modified Nylon 6 Products

5% Impact Modified PA6 |

15% Impact Modified PA6 |

25% Impact Modified PA6 |

40% Impact Modified PA6 |

|

| Tensile Strength | 50 MPa | 45 MPa | 40 MPa | 30 MPa |

| Elongation at Break | >100% | >100% | >100% | >200% |

| Impact Strength (Notched) | 20 kJ/m² | 27 kJ/m² | NB | NB |

| Density | 1.12 g/cm³ | 1.1 g/cm³ | 1.06 g/cm³ | 1.02 g/cm³ |

Applications

5% Low-Temperature Impact Resistant Nylon 6 is commonly used in stroller accessories, household items, and other applications requiring elasticity, impact resistance, and basic rigidity.

Technical Properties

Swipe Right to View Full Details

| Properties | Test Method | Units | Conditions | Value |

|---|---|---|---|---|

| Density | ISO 1183 | g/cm3 | Dry | 1.12 |

| Tensile strength at break | ISO 527 (50mm/min) |

Mpa | Dry Cond. |

50 35 |

| Elongation at break | ISO 527 (50mm/min) |

% | Dry Cond. |

>100 >150 |

| Impact strength | ISO 180-1C Charpy,23℃ |

Kj/㎡ | Dry Cond. |

72 80 |

| Impact strength | ISO 180-1C Charpy,-30℃ |

Kj/㎡ | Dry Cond. |

68 75 |

| Notched impact strength | ISO 180-1A Charpy,23℃ |

Kj/㎡ | Dry Cond. |

20 26 |

| Notched impact strength | ISO 180-1A Charpy,-30℃ |

Kj/㎡ | Dry Cond. |

18 25 |

| Melting point | ISO 3146C DSC | ℃ | Dry | 230 |

| Heat deflection temperature HDT/A | ISO 75 0.45 Mpa | ℃ | Dry | 157 |

Recommended Reading and Related Resources

Contact Us

Need further technical consultation about impact modified Nylon 6? Please feel free to contact our team. We are committed to providing you with the best solutions.

Download file