ASZ1

- 5% Impact Modified PA66

- Available in Natural, Black, or Custom Color Options

- Product Benefits: Low-Temperature Impact Resistance, High Toughness, Surface Modification

- Certificate: RoHS, REACH

- Scroll down to download PDF version

5% Impact-Modified Nylon 66

Product Overview

5% Impact-Modified Nylon 66 (5% Impact Modified PA66) is a high-toughness, fatigue-resistant nylon material designed for applications requiring enhanced mechanical properties. Compared to Nylon 6, Nylon 66 offers superior heat resistance, creep resistance, and mechanical strength. Reinforced with an impact modifier, this material features excellent impact toughness while maintaining the high rigidity characteristic of Nylon 66, making it ideal for demanding environments.

PA66 5% Impact-Modified not only enhances impact resistance but also reduces warpage during processing, making it suitable for automotive structural parts, industrial equipment, outdoor gear, and high-strength household goods.

Technical Specifications

-

Base Material: Nylon 66 (PA66/ Polyamide 66/ Nylon 66)

-

Impact Modifier Content: 5% Acid-Modified Elastomer

-

Tensile Strength: 60 MPa

-

Elongation at Break: >70%

-

Notched Impact Strength (23℃): 25 kJ/m²

-

Specific Gravity/Density: 1.14 g/cm³

-

Melting Point: 255°C

-

Color: Natural, Black, or Custom Colors

Applications

5% Impact-Modified Nylon 66 is widely used in automotive, industrial equipment, outdoor gear, and more:

-

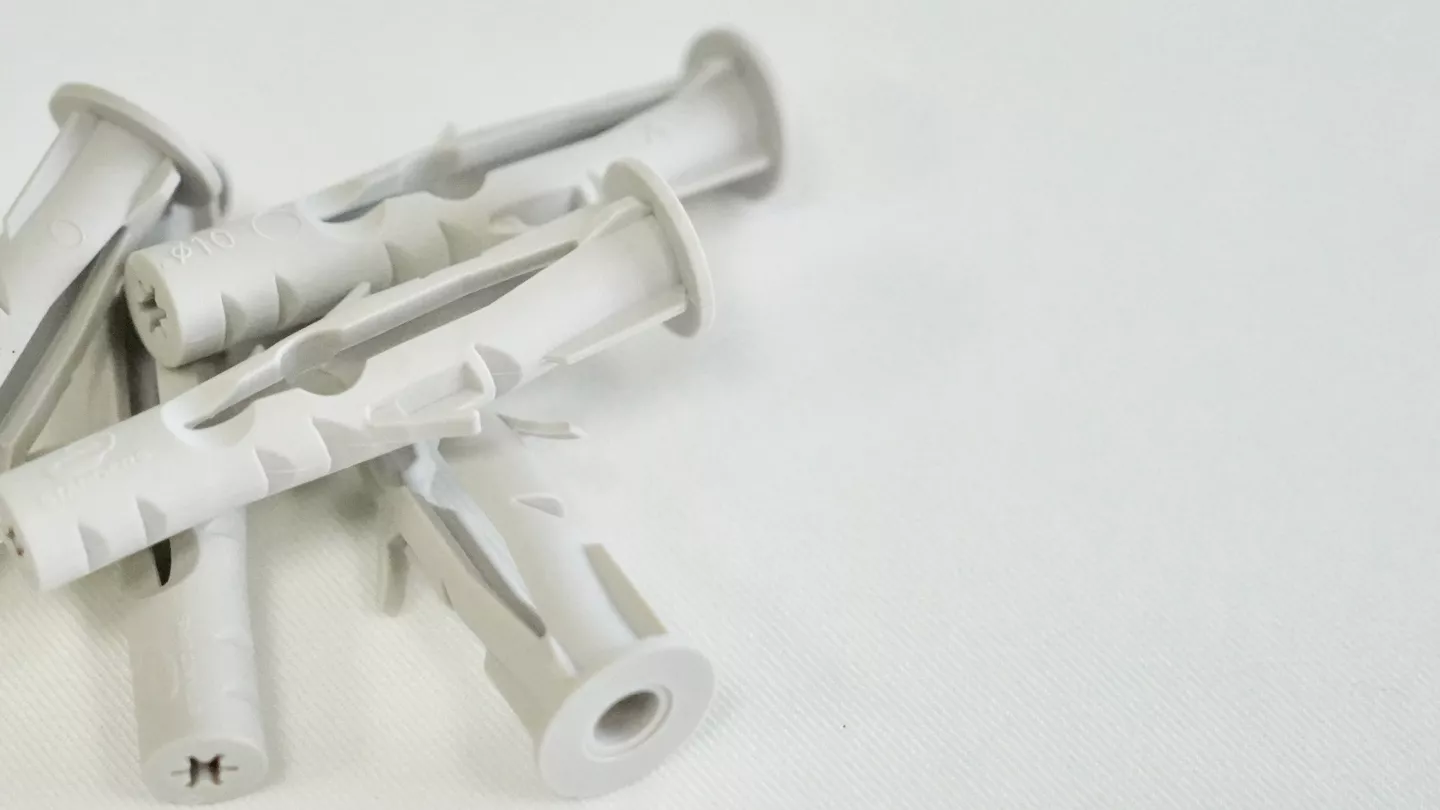

Automotive Components: Such as interior door brackets and bumper reinforcements, providing reliable performance under high-load conditions.

-

Outdoor Equipment: Such as climbing buckles and tool case housings, with excellent weather resistance and impact performance.

Comparison with Other Nylon Impact-Modified Products

| PA66 5% Impact | PA66 15% Impact | PA66 20% Impact | PA66 25% Impact | PA66 40% Impact | |

| Tensile Strength | 60 MPa | 48 MPa | 45 MPa | 43 MPa | 33 MPa |

| Elongation at Break | >70% | >100% | >100% | >100% | >200% |

| Impact Strength (Notched) | 19 kJ/m² | 25 kJ/m² | NB | NB | NB |

| Specific Gravity/Density | 1.14 g/cm³ | 1.1 g/cm³ | 1.07 g/cm³ | 1.06 g/cm³ | 1.02 g/cm³ |

Product Applications

5% Impact-Modified Nylon 66 is ideal for automotive components, industrial equipment, and outdoor gear where high rigidity and toughness are essential.

Technical Properties

Swipe Right to View Full Details

| Properties | Test Method | Units | Conditions | Value |

|---|---|---|---|---|

| Density | ISO 1183 | g/cm3 | Dry | 1.12 |

| Tensile strength at break | ISO 527 (50mm/min) |

Mpa | Dry Cond. |

55 38 |

| Elongation at break | ISO 527 (50mm/min) |

% | Dry Cond. |

>100 >150 |

| Impact strength | ISO 180-1C Charpy,23℃ |

Kj/㎡ | Dry Cond. |

71 78 |

| Impact strength | ISO 180-1C Charpy,-30℃ |

Kj/㎡ | Dry Cond. |

67 73 |

| Notched impact strength | ISO 180-1A Charpy,23℃ |

Kj/㎡ | Dry Cond. |

19 25 |

| Notched impact strength | ISO 180-1A Charpy,-30℃ |

Kj/㎡ | Dry Cond. |

17 23 |

| Melting point | ISO 3146C DSC | ℃ | Dry | 260 |

| Heat deflection temperature HDT/A | ISO 75 0.45 Mpa | ℃ | Dry | 238 |

Recommended Reading and Related Resources

-

15% Impact-Modified Nylon 66

-

20% Impact-Modified Nylon 66

-

25% Impact-Modified Nylon 66

-

40% Impact-Modified Nylon 66

Contact Us

Need further technical consultation on impact-modified Nylon 66? Feel free to contact our team. We are dedicated to providing you with the best solutions.

Download file