ASZ5

- 25% Impact Modified PA66

- Available in Natural, Black, or Custom Color Options

- Product Benefits: Low-Temperature Impact Resistance, High Toughness, Surface Modification

- Certificate: RoHS, REACH

- Scroll down to download PDF version

25% Low-Temperature Impact-Modified Nylon 66

Product Overview

25% Low-Temperature Impact-Modified Nylon 66 (25% Impact Modified PA66) is a high-toughness, cold-resistant nylon material with excellent impact resistance and dimensional stability, designed for demanding environmental applications. Enhanced with a high ratio of impact modifiers, it offers superior toughness, reduces warpage during injection molding, and maintains high rigidity characteristics.

PA66 25% Impact-Modified material is particularly suitable for sports equipment, household goods, and outdoor gear requiring extreme elasticity and strength. It also maintains stable performance in humid environments.

Applications

25% Low-Temperature Impact-Modified Nylon 66 is widely used in automotive, electronics, office furniture, and more:

-

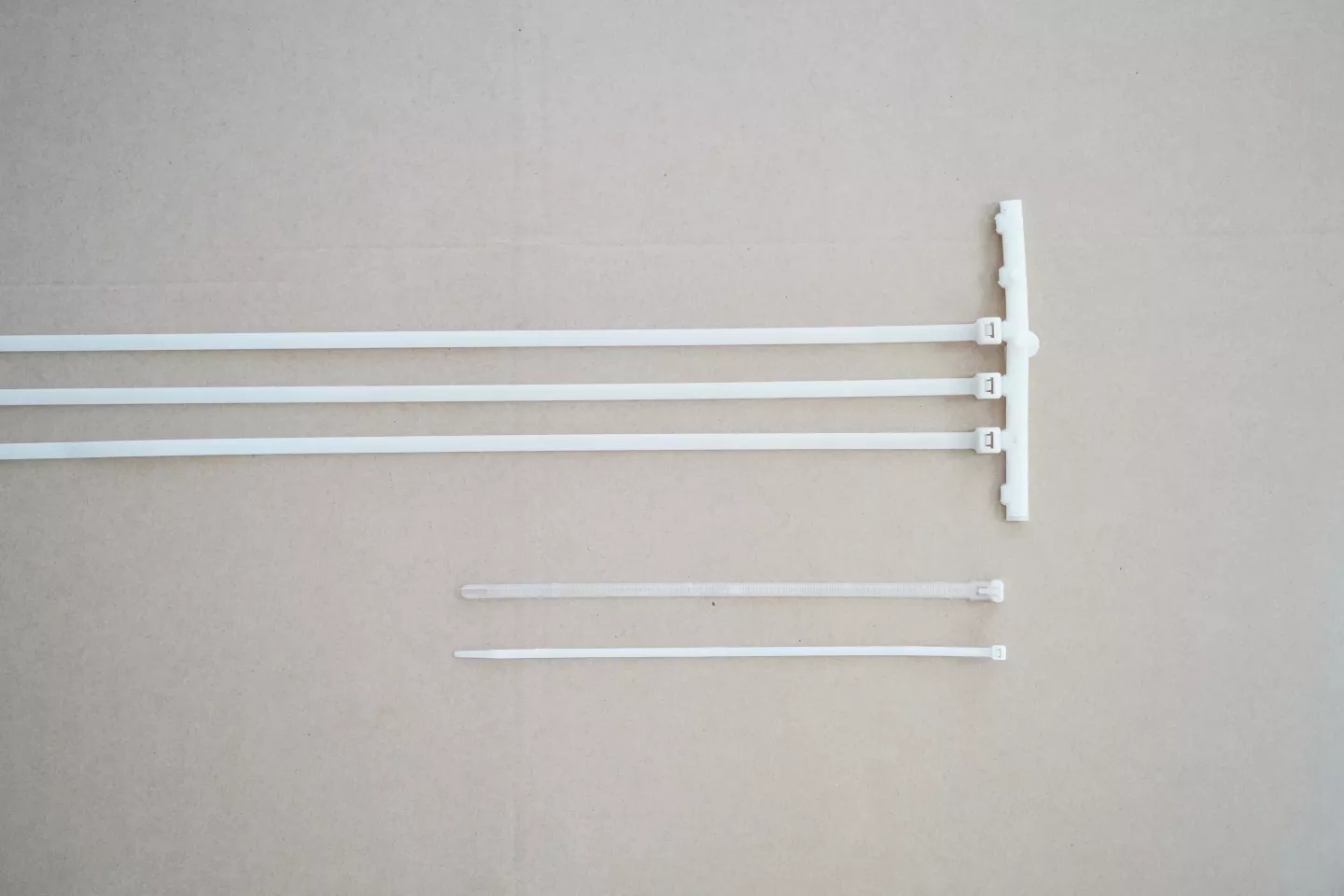

Household Goods: Such as cable ties and wall plugs, providing high impact resistance.

-

Sports Equipment: Such as binoculars, snow boots, and safety shoes. Its excellent elasticity and rigidity make it an ideal choice for these applications.

Technical Specifications

-

Base Material: Nylon 66 (PA66/ Polyamide 66/ Nylon 66)

-

Impact Modifier Content: 25% Acid-Modified Elastomer

-

Tensile Strength: 43 MPa

-

Elongation at Break: >100%

-

Notched Impact Strength (23℃): NB

-

Specific Gravity/Density: 1.06 g/cm³

-

Melting Point: 260°C

-

Color: Natural, Black, or Custom Colors

Comparison with Other Nylon Impact-Modified Products

PA66 25% Impact |

PA66 5% Impact |

PA66 15% Impact |

PA66 20% Impact |

PA66 40% Impact |

|

| Tensile Strength | 43 MPa | 55 MPa | 48 MPa | 45 MPa | 33 MPa |

| Elongation at Break | >100% | >100% | >100% | >100% | >200% |

| Impact Strength (Notched) | NB | 19 kJ/m² | 25 kJ/m² | NB | NB |

| Specific Gravity/Density | 1.06 g/cm³ | 1.12 g/cm³ | 1.1 g/cm³ | 1.07 g/cm³ | 1.02 g/cm³ |

Applications

25% Low-Temperature Impact-Modified Nylon 66 is suitable for sports equipment, household goods, and other applications requiring high toughness, impact resistance, and rigidity.

Technical Properties

Swipe Right to View Full Details

| Properties | Test Method | Units | Conditions | Value |

|---|---|---|---|---|

| Density | ISO 1183 | g/cm3 | Dry | 1.06 |

| Tensile strength at break | ISO 527 (50mm/min) |

Mpa | Dry Cond. |

43 31 |

| Elongation at break | ISO 527 (50mm/min) |

% | Dry Cond. |

>100 >150 |

| Impact strength | ISO 180-1C Charpy,23℃ |

Kj/㎡ | Dry Cond. |

NB NB |

| Impact strength | ISO 180-1C Charpy,-30℃ |

Kj/㎡ | Dry Cond. |

NB NB |

| Notched impact strength | ISO 180-1A Charpy,23℃ |

Kj/㎡ | Dry Cond. |

NB NB |

| Notched impact strength | ISO 180-1A Charpy,-30℃ |

Kj/㎡ | Dry Cond. |

90 NB |

| Melting point | ISO 3146C DSC | ℃ | Dry | 260 |

| Heat deflection temperature HDT/A | ISO 75 0.45 Mpa | ℃ | Dry | 142 |

Recommended Reading and Related Resources

-

5% Impact-Modified Nylon 66

-

15% Impact-Modified Nylon 66

-

20% Impact-Modified Nylon 66

-

40% Impact-Modified Nylon 66

Contact Us

Need further technical consultation on impact-modified Nylon 66? Feel free to contact our team. We are dedicated to providing you with the best solutions.

Download file