ASG6

- PA66 GF30

- Reinforced with 30% Glass Fiber

- Available in Natural, Black, or Custom Color Options

- Characteristic: High Rigidty, Heat Resistance

- Certificate: RoHS, REACH

- Scroll down to download PDF version

- Jump to Technical Data Sheet

30% Glass Fiber Reinforced Nylon 66 (PA66 GF30)

Product Overview

PA66 30% Glass Fiber Reinforced (PA66 GF30), also referred to as PA66 GF30 material or 30 glass filled nylon, is a high-performance engineering plastic known for its excellent mechanical strength, stiffness, and high-temperature resistance. This nylon compound is particularly suitable for applications that demand long-term stability under high temperatures. Compared to Nylon 6 (PA6), PA66 offers enhanced thermal stability, strength, dimensional stability, and flatness, as well as easy processing characteristics with a smooth surface finish.

Technical Specifications

-

Base Material: Nylon 66 (PA66/ Polyamide 66)

-

Glass Fiber Content: 30%

-

Tensile Strength: 180 MPa

-

Elongation at Break: 3%

-

Notched Impact Strength (23°C/73.4°F): 13 kJ/m²

-

Specific Gravity/Density: 1.38 g/cm³

-

Melting Point: 260°C (500°F)

-

Color: Natural, black, or custom color options

Applications

PA66 GF30 is widely used in automotive, electronics, and outdoor applications that demand high rigidity, strength, and thermal performance. This glass fiber reinforced nylon 66 compound is also suitable for structural parts due to its excellent dimensional stability and durability.

-

Automotive Industry: This 30 glass filled nylon material is used for engine parts, door frame components, and more, offering outstanding mechanical performance in high-temperature and dynamic environments.

-

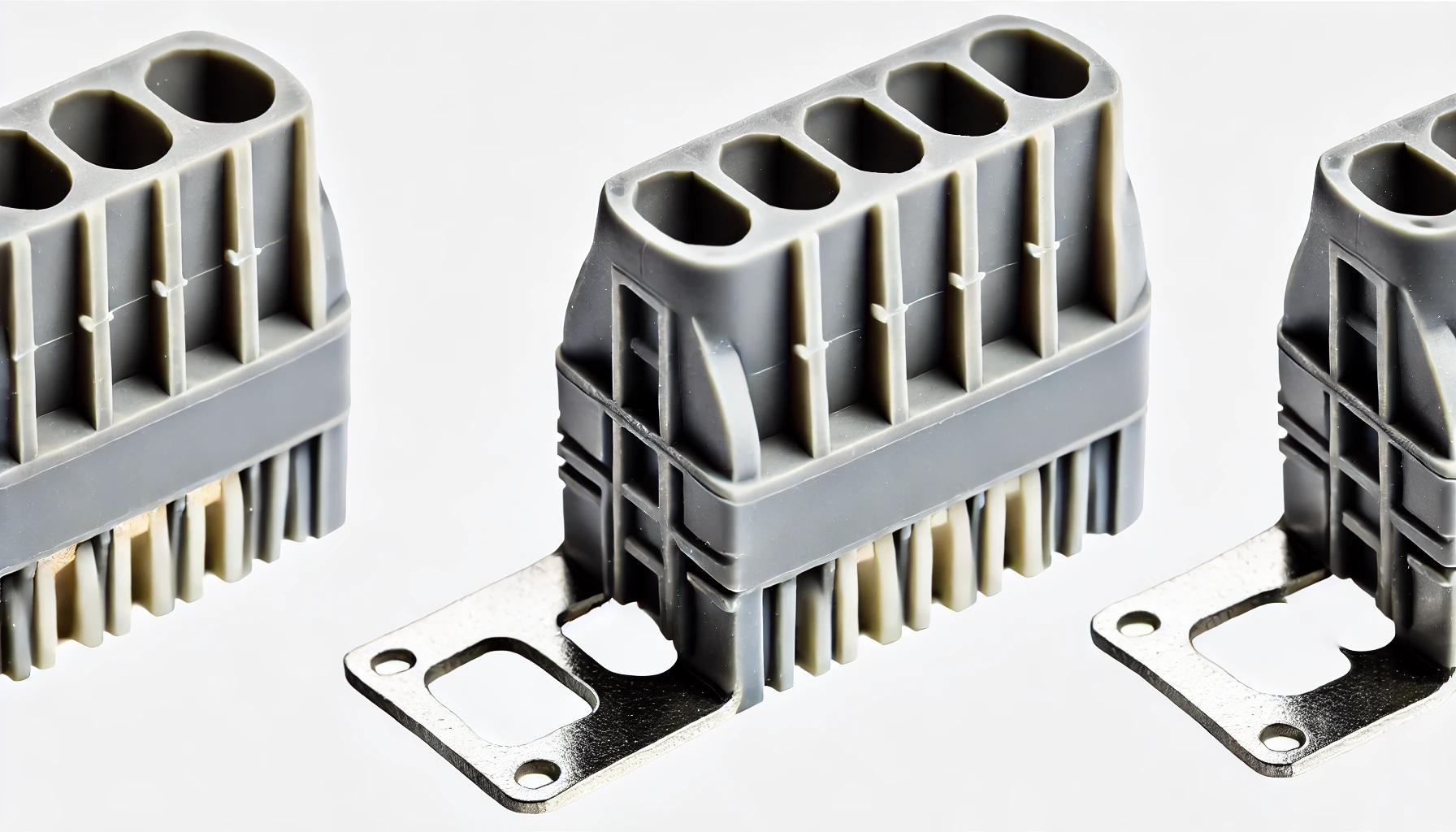

Electronics & Appliances: Ideal for connectors, plugs, and other components, PA66 GF30 provides superior insulation and heat resistance, making it an optimal choice for these applications.

-

Outdoor Equipment: This 30 glass filled nylon formulation is perfect for items like tent pegs and outdoor faucet bases, where weather resistance, durability, and rigidity are essential.

Comparison with Other Glass Fiber Reinforced Nylon Products

PA66 GF30 |

PA66 GF15 |

PA66 GF40 |

PA66 GF50 |

PA66 GF60 |

|

| Tensile Strength | 180MPa | 150MPa | 200MPa | 215MPa | 235MPa |

| Elongation at Break | 3% | 3.5% | 2.3% | 2% | 2% |

| Notched Impact Strength | 13 kJ/m² | 11 kJ/m² | 14 kJ/m² | 14 kJ/m² | 15 kJ/m² |

| Specific Gravity/Density | 1.38 g/cm³ | 1.22 g/cm³ | 1.46 g/cm³ | 1.56 g/cm³ | 1.67 g/cm³ |

Product Applications

PA66 GF30 is commonly used in automotive components, outdoor equipment, and parts that operate in high-temperature environments. This material is ideal for applications requiring high rigidity and strength.

Technical Data Sheet – PA66 GF30

The following technical properties of PA66 GF30 are based on standard ISO test methods. Values represent typical performance in dry and conditioned states.

| Properties | Test Method | Units | Conditions | Value |

|---|---|---|---|---|

| Density | ISO 1183 | g/cm3 | Dry | 1.38 |

| Tensile strength at break | ISO 527 (50mm/min) |

Mpa | Dry Cond. |

180 148 |

| Elongation at break | ISO 527 (50mm/min) |

% | Dry Cond. |

3 4 |

| Impact strength | ISO 180-1C Charpy,23℃ |

Kj/㎡ | Dry Cond. |

76 80 |

| Impact strength | ISO 180-1C Charpy,-30℃ |

Kj/㎡ | Dry Cond. |

73 78 |

| Notched impact strength | ISO 180-1A Charpy,23℃ |

Kj/㎡ | Dry Cond. |

13 13 |

| Notched impact strength | ISO 180-1A Charpy,-30℃ |

Kj/㎡ | Dry Cond. |

12 12 |

| Melting point | ISO 3146C DSC | ℃ | Dry | 260 |

Recommended Reading and Related Resources

Contact Us

If you have any questions or need further technical support, please feel free to contact our team. We are committed to providing you with the best solutions.