ENP

- Maleic Anhydride Grafted Polypropylene for PP+GF

- Product Benefits: ENP contributes to the enhancement of various Polypropylene (PP) composite materials. It improves the bond between PP and glass fiber, elevating their rigidity, tensile strength, ductility, surface gloss, and processability to the next level.

- Scroll down to download PDF version

- Jump to Technical Data Sheet

What Is ENP (Maleic Anhydride Grafted Polypropylene)?

ENP is a functionalized polypropylene grafted with maleic anhydride (MA), designed as a compatibilizer and adhesion promoter for polypropylene-based composites. It is particularly effective in improving the interfacial bonding between polypropylene (PP) and glass fibers (GF)—a common challenge in reinforced thermoplastics.

Why Is Maleic Anhydride Grafted Polypropylene (MAgPP) Essential for PP Composites?

Polypropylene is non-polar and inherently has poor adhesion to polar reinforcements like glass fibers. This weak interface often results in reduced tensile strength and impact resistance in composites. Maleic Anhydride Grafted Polypropylene (MAgPP), like ENP, is engineered to overcome this issue by introducing polar functional groups into the PP matrix, significantly enhancing bonding and overall composite performance.

🔗 Read more about PP GF composites here.

ENP: A High-Performance Coupling Agent for PP+GF Composites

ENP is a high-efficiency coupling agent and compatibilizer developed to improve bonding between polypropylene and glass fiber. By grafting maleic anhydride (MA) functional groups onto a PP backbone, ENP introduces polarity into the matrix, significantly increasing interfacial adhesion. ENP introduces polar functional groups that react chemically with the surface of glass fibers, making it an excellent adhesion promoter for polypropylene composites. As a high-performance PP composite modifier, it enhances strength, impact resistance, and ductility, all while maintaining the lightweight and processable characteristics of PP.

Key Benefits of ENP:

-

Enhances tensile strength by up to 100%

-

Improves elongation at break and impact strength

-

Promotes better fiber dispersion, surface finish, and moldability

-

Maintains excellent chemical resistance and lightweight properties

-

Acts as a high-performance PP composite modifier across industries

How ENP Works – Chemistry Meets Performance

ENP enables significantly stronger interfacial adhesion and improves the mechanical performance of the final composite.

Typical Use Levels: 10–20% ENP in PP+GF formulations

Use Case Examples: Automotive under-the-hood parts, home appliance housings, electrical enclosures, and recycled PP products requiring consistent adhesion.

Application Fields for ENP (MAgPP)

ENP is a versatile additive, ideal for both virgin and recycled PP systems. Common applications include:

-

PP+GF Compounds

-

Recycled PP Material Enhancement

-

Mineral-Filled Polypropylene Systems

-

Wood-Plastic Composites (WPC)

-

Lightweight Structural Applications

-

As a coupling agent for recycled polypropylene, ENP helps restore strength and consistency.

Frequently Asked Questions About ENP / MAgPP

Is ENP the same as MAgPP?

Yes, ENP is a proprietary name for Maleic Anhydride Grafted Polypropylene, used to improve bonding between polypropylene and fillers like glass fiber.

What industries use MAgPP coupling agents?

Common in automotive, electrical, home appliances, packaging, and construction for enhancing PP composite strength and durability.

How much ENP should be added to PP composites?

Typically 10–20% by weight is recommended to optimize adhesion and mechanical performance in PP+GF systems.

Can ENP be used in recycled PP?

Absolutely. It's an ideal coupling agent for recycled polypropylene, restoring adhesion and reinforcing mechanical properties.

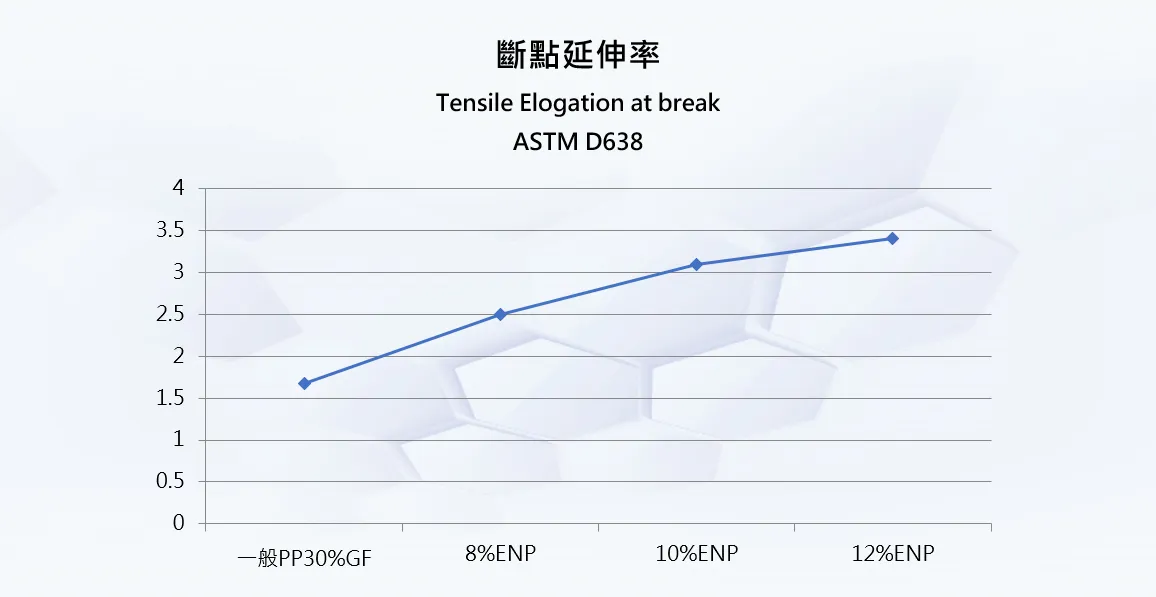

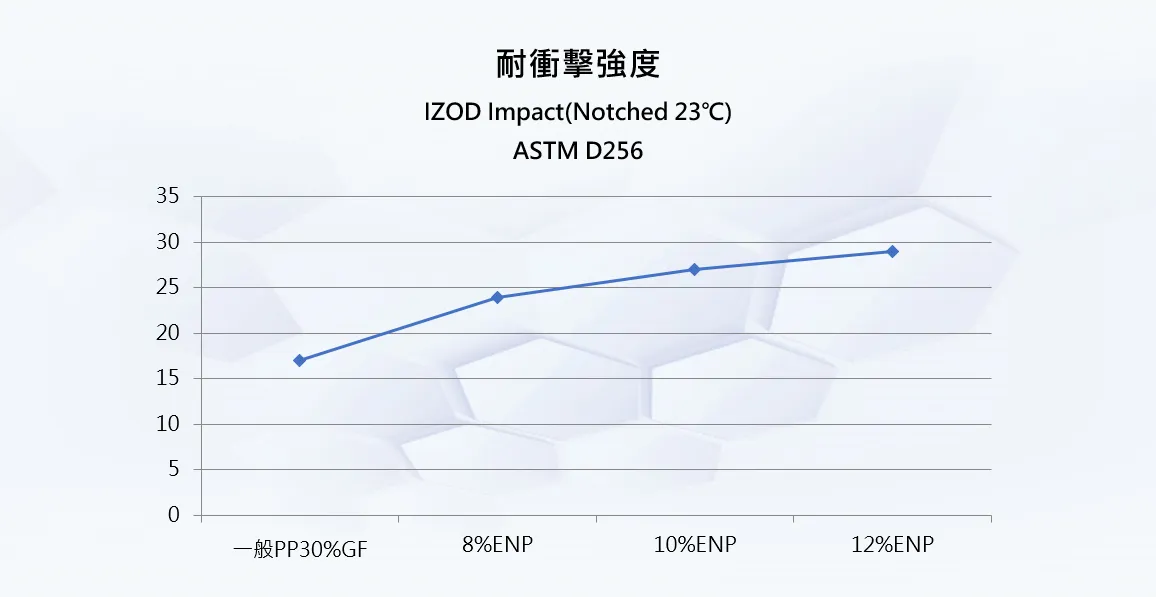

Test Results: Why ENP Matters

ENP (Maleic Anhydride Grafted Polypropylene) in PP composites with 30% glass fiber:

-

Tensile strength improved by 50%–100%

-

Impact strength increased by 10%–20%

-

Elongation at break improved by 10%–20%

These improvements make ENP ideal not just for new product development, but also for enhancing recycled or downgraded materials in circular economy strategies.

Results of Adding Various Proportions of ENP to PP+30%GF

Ready to Optimize Your PP Formulations?

Whether you're a compounder, converter, or manufacturer, ENP offers a reliable solution to upgrade the performance of your PP composites. It's a powerful Maleic Anhydride Grafted Polypropylene compatibilizer for engineers seeking better adhesion and mechanical performance in both virgin and recycled systems.

📨 Contact us now to request technical data sheets, processing guidelines, or free samples.

Technical Properties – ENP

The following technical properties of ENP are based on standard ISO test methods. Values represent typical performance in dry and conditioned states.

| Properties | Test Method | Units | Value |

|---|---|---|---|

| Density | ASTM D-792 | g/cm3 | 0.9 |

| Melt flow index | ASTM D-1238 | g/10min | >80 |

| Tensile strength at break | ASTM D-638 | Mpa | 30 |

| Elongation at break | ISO 527 (50mm/min) |

% | >100 |

| Flexural strength | ISO 178 | Mpa | 255 212 |

| Ball indentation hardness | ASTM D-2240 | ShoreA.D | 680 |

| Melting point | ISO 3146C DSC | Mpa | 155 |