1. What is PA66 (Nylon 66)?

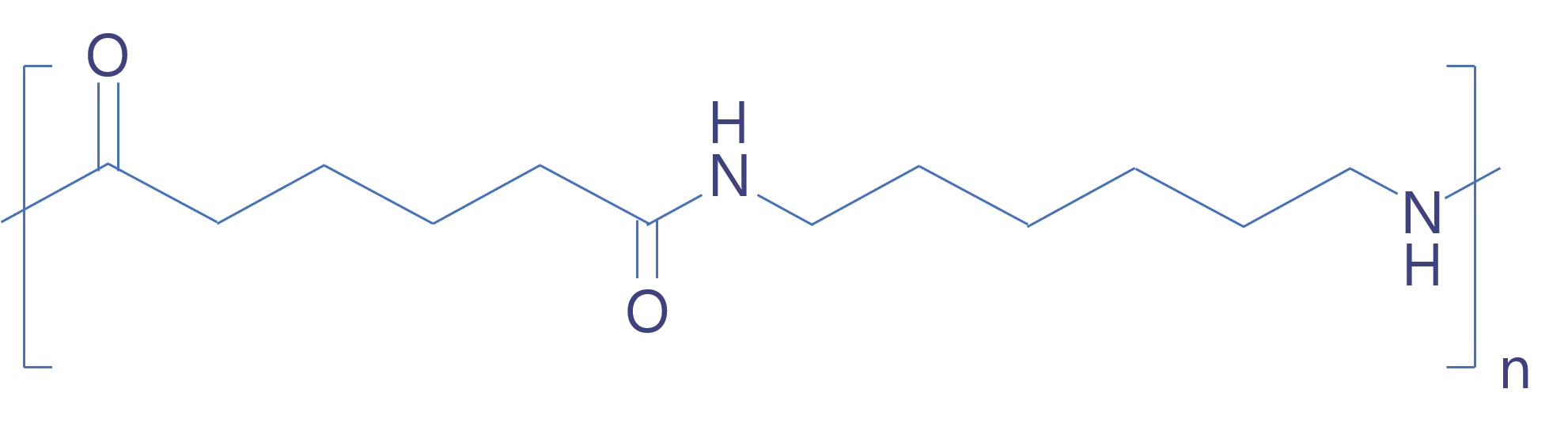

PA66, commonly known as Polyamide 66, or Nylon 66, is a high-performance engineering thermoplastic made through the polymerization of adipic acid and hexamethylenediamine. It is renowned for its superior mechanical strength, thermal stability, and chemical resistance, making it ideal for demanding industrial applications.

Learn more about PA6: 10 Insights on PA6

2. What Is PA66 Used For?

PA66 is utilized across various industries, including automotive, aerospace, electronics, and manufacturing. Common applications include gears, bearings, electrical connectors, and structural components. Its robustness and resistance to extreme conditions make it suitable for high-stress and high-temperature environments.

3. What Are the Key Properties of PA66?

- High Tensile Strength: Approximately 80-90 MPa, providing exceptional mechanical strength.

- High Melting Point: Up to 270°C, ensuring stability at elevated temperatures.

- Good Chemical Resistance: Resistant to oils, solvents, and fuels, making it ideal for chemically aggressive environments.

- Excellent Wear and Abrasion Resistance: Withstands friction and wear effectively.

- Low Moisture Absorption: Compared to PA6, PA66 absorbs less moisture, offering better dimensional stability and performance.

Learn more about the comparison between PA6 and PA66: PA6 vs PA66: Difference and Comparison

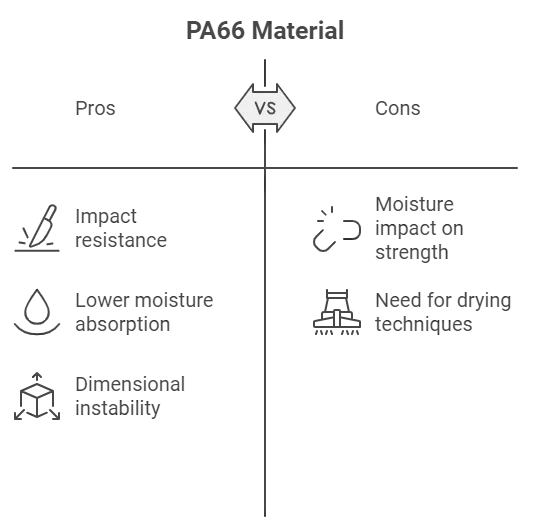

4. What Are The Disadvantages or Challenges of PA66?

Despite its benefits, PA66 faces some challenges. One notable issue is moisture absorption. Although PA66 absorbs less water than PA6, moisture can still impact its strength and dimensional stability, while potentially improving impact resistance. Proper drying techniques and environmental controls are recommended to mitigate these effects.

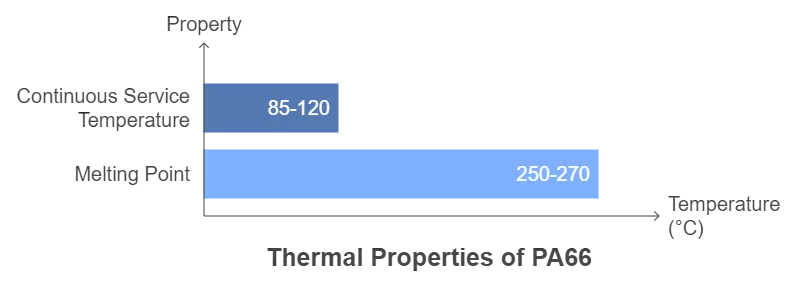

5. What Is The Temperature Limit For PA66?

PA66 is known for its high thermal stability, with a continuous service temperature range of up to 85-120°C. This allows it to maintain its mechanical properties and performance even under prolonged exposure to high temperatures. The high melting point of PA66, ranging between 250-270°C, further enhances its thermal performance.

6. Is PA66 Recyclable?

Yes, PA66 is recyclable. It can be reprocessed and reused in various applications, supporting sustainability efforts in manufacturing. Recycling PA66 helps reduce environmental impact and promotes a circular economy by reintroducing valuable materials back into production.

7. Is PA66 Wear-Resistant?

PA66 exhibits excellent wear resistance, making it suitable for applications involving moving parts and high-stress environments. Its durability ensures long-lasting performance even under demanding conditions.

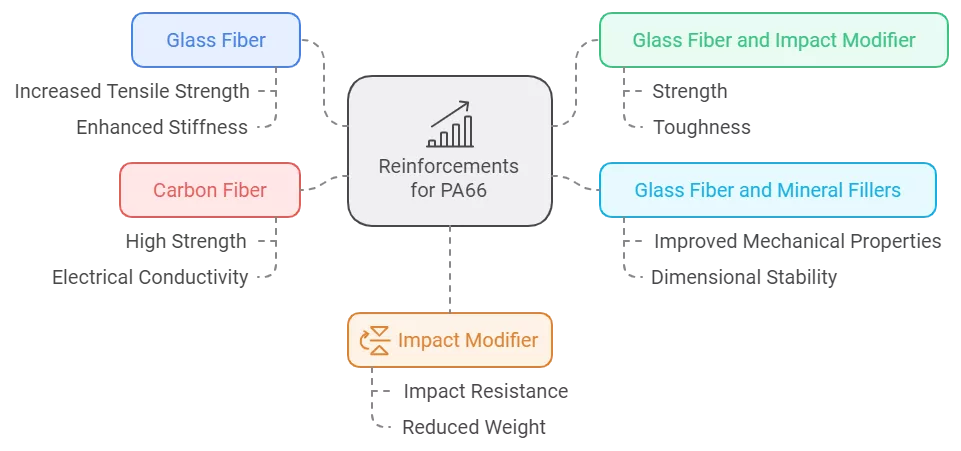

8. What Materials are Commonly Reinforced with PA66?

PA66 can be reinforced with various materials to enhance its properties:

- Glass Fiber: Increases tensile strength and stiffness, making the material more rigid and robust.

- Glass Fiber and Impact Modifier: Combines strength and toughness, with glass fiber for stiffness and impact modifiers for improved durability.

- Glass Fiber and Mineral Fillers: Provides a balance of improved mechanical properties and dimensional stability.

- Carbon Fiber: Boosts strength and electrical conductivity, suitable for high-performance applications.

- Impact Modifier: Improves impact resistance and reduces weight, particularly useful in structural applications.

Learn more about our PA66 product catalog: PA66 Product Catalog

Still Not Sure If PA66 Is The Best Material For Your Product?

At All Around Compounding (All Around Polymer) Co., Ltd., we don't just provide high-quality nylon compounds; we work closely with you to identify the most suitable materials for your specific applications. Our team of experts will evaluate your requirements, considering factors such as mechanical strength, temperature resistance, and environmental conditions, to recommend the optimal solution.

For example, one of our clients in the automotive industry successfully replaced metal components with our reinforced PA66, achieving significant weight reduction and improved fuel efficiency without compromising strength. If you're interested in learning more about alternatives to metal in manufacturing, explore our guide on Top Plastics for Metal Replacement.

Our commitment to personalized support ensures that you get the best material for your needs, backed by our deep industry knowledge and technical expertise. Contact us today at info@aaccl.com to discuss how our PA66 solutions and tailored recommendations can elevate your products and projects.