Why Plastics Are Replacing Metals in Manufacturing

In today's fast-paced manufacturing industries, replacing metals with plastics has become a game-changer. Many industries, from automotive to consumer goods, are replacing metals with plastics to find lighter, more cost-effective, and corrosion-resistant materials. These materials are reshaping how products are designed and produced, reducing energy consumption and improving efficiency.

This article explores the top plastics for metal replacement, their applications, and why they are the materials of choice for high-performance industries.

Top Metal Replacement Plastics : Pros, Cons & Applications

When it comes to metal replacement, not all plastics are created equal. Here are the top engineering plastics that stand out for their unique properties:

-

Polypropylene (PP)

PP is lightweight, chemically resistant, and cost-effective, making it a practical alternative to metal for non-structural components.- Pros: Chemical resistance, good fatigue resistance, low density.

- Cons: UV degradation, low temperature resistance.

- Applications: Consumer goods, automotive interiors, and packaging.

-

Polyamide (PA/Nylon)

Polyamide (PA), commonly known as nylon, is a high-strength, durable material with excellent wear resistance. Both PA6 and PA66 are popular choices for their versatility and ability to be reinforced with glass fiber for added strength.- Pros: Impact resistance, high strength, modifiable, good wear resistance, excellent chemical resistance, high temperature resistance, UV resistance.

- Cons: Hygroscopic (absorbs moisture).

- Applications: Automotive components, industrial parts, and electronics.

-

Polyether Ether Ketone (PEEK)

PEEK excels in extreme conditions, offering high heat resistance, mechanical strength, and excellent chemical resistance. It is ideal for demanding applications where metals traditionally dominate.- Pros: Excellent mechanical strength, high temperature and chemical resistance.

- Cons: Very high cost, requires high processing temperatures.

- Applications: Aerospace, medical devices, and high-temperature environments.

-

Polytetrafluoroethylene (PTFE)

PTFE, known for its low friction and exceptional heat resistance, is a top choice for applications requiring smooth surfaces and durability in harsh environments.- Pros: Extremely high chemical resistance, excellent thermal stability.

- Cons: Very high cost, difficult to process, significant environmental impact.

- Applications: Seals, gaskets, and chemical-resistant components.

Why Are Manufacturers Switching from Metal to Plastics?

Plastics have distinct advantages over metals in manufacturing, including:

Weight Reduction

Plastic products are much lighter than metal products, which helps improve vehicle fuel efficiency and effectively reduces carbon emissions.

Thermal and Electrical Performance

Plastics excel in providing good thermal resistance and excellent electrical insulation, making them suitable for applications like electronic housings and automotive parts.

Cost-Effectiveness

Considering production and processing costs, plastic products are generally more affordable in both material and production costs compared to metal products.

Corrosion Resistance

Unlike metals, many plastics are resistant to rust and corrosion, reducing maintenance costs and extending product life.

Design Flexibility

Plastics offer greater flexibility in injection molding, allowing for complex and precise designs compared to metal processing.

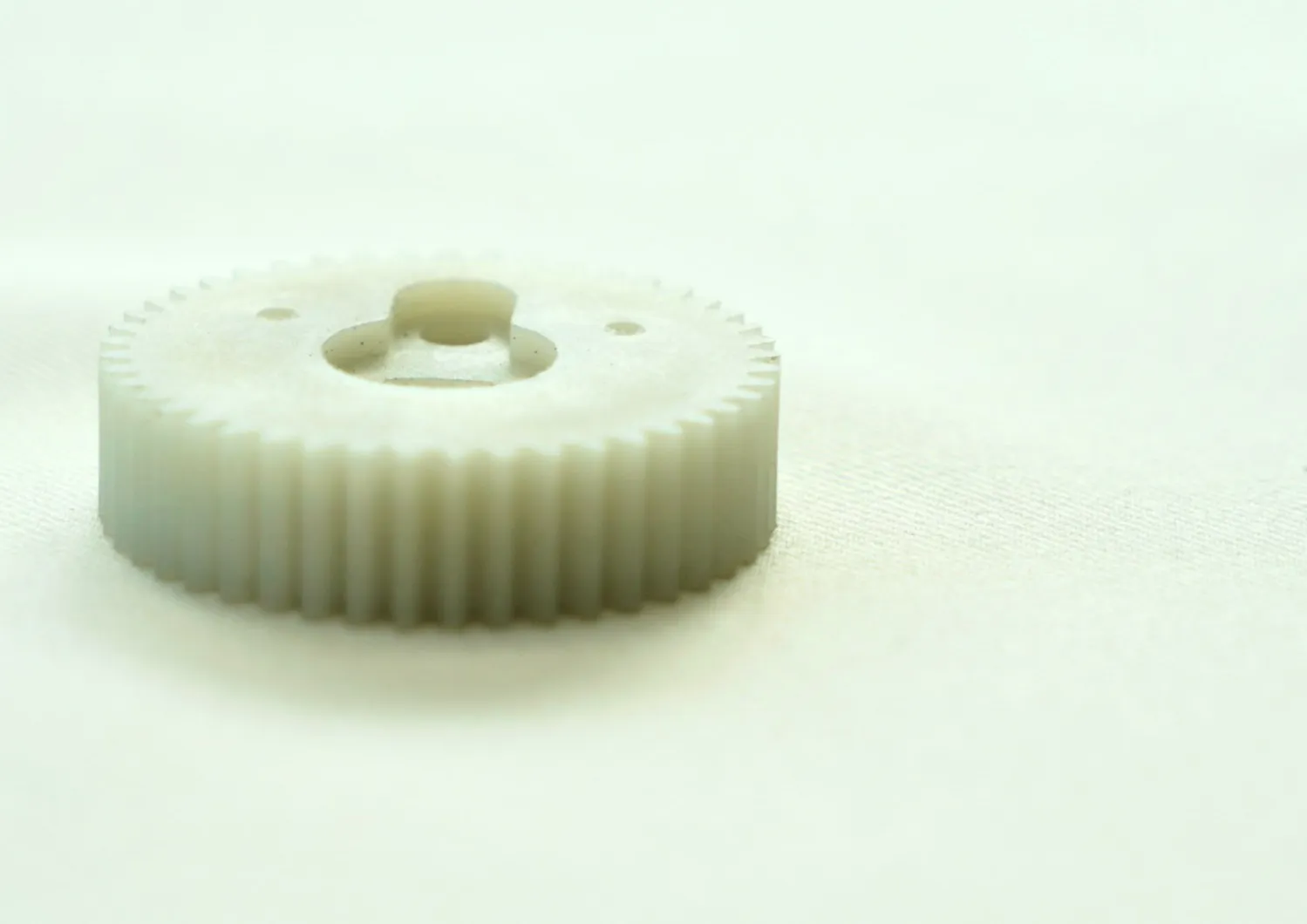

Noise and Vibration Reduction

Plastics reduce noise and vibration due to their inherent flexibility, making them ideal for components like gears, engine mounts, and furniture parts.

Plastic vs. Metal: A Comparative Analysis

| Aspect of Comparison | Plastics | Metals |

| Weight | Lighter, enhances fuel efficiency | Heavier, affects weight and efficiency. |

| Cost | Corrosion-resistant, reduces maintenance costs | Higher cost due to material and processing. |

| Corrosion Resistance | Corrosion-resistant, reduces maintenance costs | Prone to corrosion, requires coatings or treatments. |

| Design Flexibility | Easily molded, allows for complex shapes | Limited flexibility in shapes, often requires multiple processes. |

| Mechanical Performance | Varied performance: High strength, rigidity, and impact resistance | Prone to fatigue, susceptible to impact damage. |

| Environmental Impact | Lower impact, depending on recyclability | Significant impact from extraction to disposal. |

Why Nylon Composites Are the Best Choice for Metal Replacement

Among the many plastics available for metal replacement, nylon composites stand out as an ideal choice due to their excellent performance and versatility. By combining nylon with glass or carbon fibers, the strength and durability of these materials are significantly enhanced.

High Glass Fiber Reinforced Nylon (Up to 70% GF)

Our metal replacement nylon composites products can contain up to 70% glass fiber. When the glass fiber content reaches 40%, the material's rigidity and strength reach high levels, making it a viable replacement for metals in many high-strength applications. This high glass fiber content not only enhances tensile and flexural strength but also provides excellent dimensional stability and fatigue resistance, especially suitable for industrial environments requiring high temperature and mechanical performance.

Carbon Fiber Reinforced Nylon (Up to 40% CF)

Additionally, our nylon composite products can contain up to 40% carbon fiber, further enhancing the material's rigidity, wear resistance, and low density characteristics, making it ideal for high-performance applications like aerospace and automotive parts.

With these outstanding properties, our nylon composites can successfully replace metals in many applications while offering a lighter, more durable solution.

To learn more about our nylon composite products, please refer to our high glass fiber reinforced nylon product line and carbon fiber reinforced nylon product line.

Why Choose Nylon Composites Over Other Plastics?

Reasons to choose nylon composites over other general-purpose plastics include:

-

High mechanical strength and toughness: Suitable for high-strength applications, able to withstand significant impacts without breaking.

-

Excellent wear resistance: Reduces wear in friction parts, extending the life of gears and bearings.

-

Strong chemical resistance: Resistant to various chemicals, oils, and fuels, making nylon composites suitable for harsh environments where metals may corrode.

-

Low coefficient of friction: Improves efficiency and longevity of mechanical systems.

-

Superior thermal stability: Maintains performance across a wide range of temperatures.

-

Optimized moisture absorption: By compounding with reinforcing materials or additives, moisture absorption issues can be minimized, ensuring stability in humid environments.

Industries & Applications of Nylon Composites

1. Automotive Industry

Nylon composites are widely used in structural components due to their light weight and high strength.

-

Applications: Fuel tanks, headlight housings, side mirrors.

2. Office Furniture

Due to their high strength, durability, and versatility, nylon composites are widely used in various office furniture components, including chair legs, armrests, and height adjustment parts.

- Applications: Chair armrests, chair legs, height adjustment mechanisms.

3. Electronics and Appliances

Nylon composites offer electrical insulation and mechanical strength, making them ideal for manufacturing connectors, housings, light brackets, and other electronic components.

- Applications: Connectors, light brackets, switch housings.

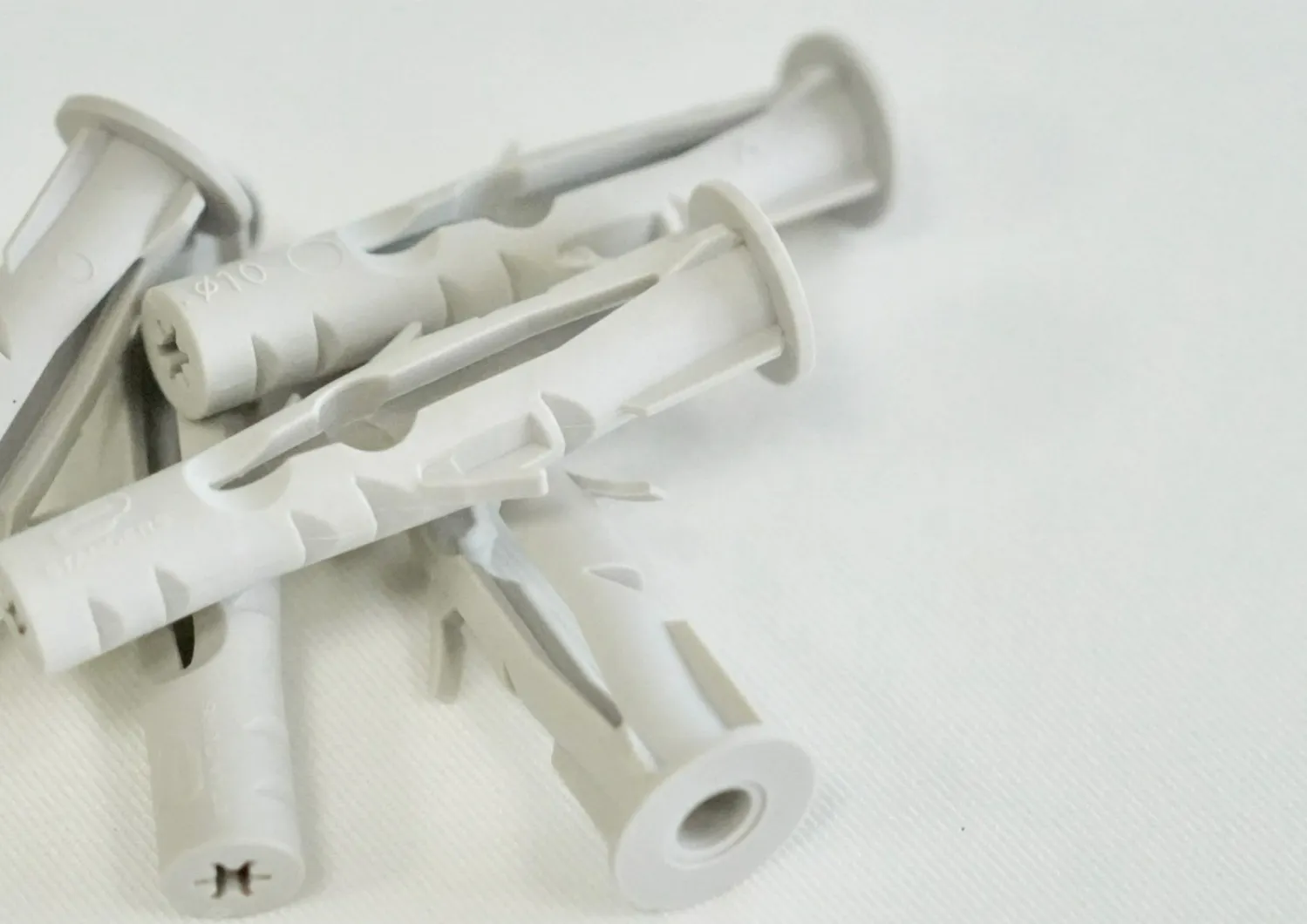

4. Industrial Machinery

Nylon composite gears, bearings, and wear-resistant parts perform reliably in demanding industrial environments, offering long service life and reducing downtime.

- Applications: Gears, wall anchors, bicycle bottle cages.

Read More: Wide Applications of Nylon Composites

Case Study: Lightweight and Sustainable Revolution - Nylon 60% GF in Solar Power

The Challenge

Traditional materials like aluminum in solar panels are heavy, costly, and prone to corrosion. Manufacturers need stronger, lighter, and more sustainable alternatives.

The Solution: Nylon 60% GF

Nylon reinforced with 60% glass fiber is a high-performance material offering:

- Exceptional Strength: Comparable to aluminum but far lighter.

- Corrosion Resistance: Long-lasting in harsh outdoor environments.

- Cost Efficiency: Reduced production and transport costs with injection molding.

Applications in Solar Panels

Nylon reinforced with 60% glass fiber is a high-performance material offering:

- Frames: Lightweight and durable, reducing installation and transport costs.

- Brackets and Mounting Systems: Withstands heavy loads and extreme weather.

- Cable Management: Provides electrical insulation and environmental protection.

The Result of applying Nylon 60% GF to Replace Metal

A solar company replaced aluminum frames with Nylon 60% GF, achieving:

- 40% weight reduction.

- 20% lower production costs.

- 80% more durable in coastal and desert climates.

Sustainability Considerations

While plastics offer numerous advantages, sustainability is a key consideration:

- Recyclability: Modern plastics like PA and PP are increasingly recyclable, reducing environmental impact.

- Energy Efficiency: The lightweight nature of plastics reduces energy consumption during transport and manufacturing.

- Lifecycle Analysis: Plastics often have a lower carbon footprint over their lifecycle compared to metals, especially in lightweighting applications.

Conclusion: The Future of Metal Replacement with Nylon Composites

The transition from metals to plastic composites, especially nylon composites, represents a significant advancement in material science, meeting today's manufacturing demands for sustainability, efficiency, and innovation. Nylon composites, with their superior adaptability and performance, are becoming the preferred choice for replacing metals, particularly for industries looking to streamline processes, reduce costs, and enhance product performance.

1. Material Advantages:

Nylon composites offer exceptional strength, durability, and adaptability, making them stand out in a variety of applications. They maintain stability in high-pressure, high-temperature environments and provide excellent impact resistance, making them ideal for demanding industrial conditions.

2. Manufacturing Advantages:

These materials can significantly simplify the manufacturing process, reducing dependency on metal raw materials while boosting production efficiency. Whether for automotive parts, aerospace components, or consumer goods, nylon composites provide lightweight, durable, and cost-effective solutions.

3. Application Scenarios:

Nylon composites excel in various applications, such as enhancing the performance of automotive parts like headlight housings, reducing the weight of aerospace components, and increasing the durability of consumer goods. Additionally, for applications requiring impact-modified nylon, its reinforced toughness and durability make it an ideal choice for injection molding in demanding environments.

Nylon composites can help you gain an edge in production by leveraging their superior performance to meet the demands of efficient manufacturing. Whether you're looking to improve the performance of automotive parts like headlight housings, reduce the weight of aerospace components, or increase the durability of consumer goods, nylon composites offer reliable and efficient solutions. For applications requiring impact-modified nylon for injection molding, its enhanced toughness and durability make it an ideal choice for harsh environments.

Contact Us

Looking to replace metal with high-performance nylon composites? Contact our team to learn how nylon composites can revolutionize your manufacturing processes and products. Let us help you innovate and succeed in a competitive market.